Dry barrel hydrants get their name from the fact that water is drained or pumped from the barrel when the hydrant is not in use. Dry barrel design eliminates damage to the hydrant caused by freezing or corrosion of the upper part.

Ad Female Male Dry Fire Hydrants.

. Dry barrel design eliminates damage to the hydrant caused by freezing or corrosion. Dry Hydrant Design Solutions Menu. EJ designs continue to evolve to meet the changing needs of water systems which now include the option to have a 250 or 350 psi.

Wet Barrel Fire Hydrant. The department risks losing suction due to leaks from pump seals and or hydrant fittings. Since the storage of water is above ground wet barrel hydrants are easy to install.

1-tier bonnet 1 pc. DRY HYDRANT DESIGN A typical dry hydrant drawing is shown on the front cover page. DRY BARREL HYDRANTS FEATURES AVK dry barrel hydrants meet or exceed AWWA C502 Modern or nostalgic styles available with interchangeable internal parts ULULC listed and FM approved Certified to NSFANSI 61 NSFANSI 372 High pressure rating 250 PSI High strength ductile iron nozzle section barrel section and base.

To do this one must adapt the Dry Hydrant concept to fit local needs whatever they may be. One design of high pressure hydrant is the high pressure pilot-valve hydrant. Unpressurized hydrants are always a drybarrel design.

In colder climates dry barrel hydrants will be required which use a single operating valve that is located below ground in the base of the riser and. Same Day Shipping On All Dry Hydrant Accessories Strainers Caps Plugs. The wet barrel fire hydrant provides a steady flow of water whereas the dry barrel fire hydrant requires a valve release to allow water to enter.

See reviews photos directions phone numbers and more for Fire Hydrant Repair Co locations in Piscataway NJ. In making your decision it is our recommendation the following guidelines be used. It is also referred to as.

As a critical piece of any emergency response system used to preserve lives and property all Mueller fire hydrants are designed built and tested to assure high performance long life and dependability. Although fire hydrants are often used for other purposes their primary function is to supply. Dry barrel hydrants are pressurized and drained through the workings of a main valve located in the base of the hydrant.

Dry-barrel hydrants are usually used where winter temperatures fall below 32 F 0 C to prevent the hydrant from freezing. A recessed hydrant below ground-level connection may be specified for use in areas with special needs such as in a high vandalism area or for low profile and esthetic needs. This makes dry barrel hydrants an.

EJ primarily offers two styles of dry-barrel fire hydrants. This can be used to determine how much water will be available from your dry hydrant. Available in Bury Depths from 36 to 72 Safety coupling and flange design reduce traffic damage to the hydrant.

We are happy to answer questions you might have about FILL-RITE hose products and help you select what you need when you need your business to function with optimal outcome. AWWA Standard for Dry Barrel Fire Hydrants C502-94 WSA guide to Water Works Design EPB-201 2012 City Of Saskatoons approved hydrant manuals. Numerous dry and wet barrel designs are available that meet stringent ULFM requirements some with maximum working pressures of 350psiFull Line Catalog.

The dry-barrel with a 45-inch and two 25-inch outlets The break-away flange which allows the hydrant to break off at ground level. Both designs operate nearly identical with the most notable difference being the exterior look of the hydrant. Dry Barrel Fire hydrants have been used in fire protection for over 100 years.

DRY HYDRANT DESIGN A typical dry hydrant drawing is shown on the front cover page. TU- Construction Design PURPOSE AND USES OF FIRE HYDRANTS. The two types of fire hydrant systems are dry barrel and wet barrel.

Elevated Ponds Tanks. Fire Brigade Connections are independent systems that. There is an old saying.

It is intended to allow immediate access to water in the case of a fire. Planning and installation of Dry Fire Hydrants. Our own 20 years of experience have made us experts in Hydrant Adapters dealer getting to know their parts modern design and function and quality performance.

The trick is to figure out how to make it usable for fighting fires. The upper section does not fill with water until the fire pumper applies a vacuum. The barrel of the hydrant is drained or pumped dry when the hydrant is not in use.

A successful Dry Hydrant program will be designed with the future growth of your fire department in mind ie 5-10 years and 1000 - 1500 gpm pumper trucks. The water in the dry barrel design is kept below ground to avoid freezing. As a practical matter dry hydrants probably should not be more than 15 feet vertical.

Dry barrel conventional hydrants may not be used due to excess suction loss and the necessity that they be absolutely airtight. Available In Straight 90 and 45 Degrees. Rapidrop Dry Barrel Hydrant comes with duck foot bend available in Flanged Mechanical Joint options.

Each installation should be designed with the capability of flowing a minimum of 1000 gpm. In temperate climates where hard freezing is not an issue the most efficient hydrant design is the wet barrel hydrant where valves are located above ground and can be independently controlled. Rapidrop FM1510 Dry barrel hydrants are designed as per AWWA C502.

Wet Barrel Hydrants are perfect for regions where theres no freezing temperature conditions. Designs Innovations and Use of Dry Hydrants. Personnel involved in installing a dry fire hydrant system are encouraged to read this booklet thoro ughly before beginning fieldwork on the project.

AWWA C502 was developed in 1913 as a standard for the manufacture and use of dry barrel hydrants. CD and BR Design Highlights. The shut-off valves are above ground so theres water in the barrel even when the hydrant is not in use.

Each outlet has a valve that operates independently and the mechanical parts are easy to access above ground and can be adjusted to the proper height without expensive modifications. Fireguard Hydrants are based on a simple design it is easy to. Since each installation will be unique in itself we will try to present an orderly method to plan for and install a Dry Fire Hydrant system.

AVK Groups Dry Barrel Fire Hydrants have an automatic drain valve that enables firefighters to engage their hose and use it when needed.

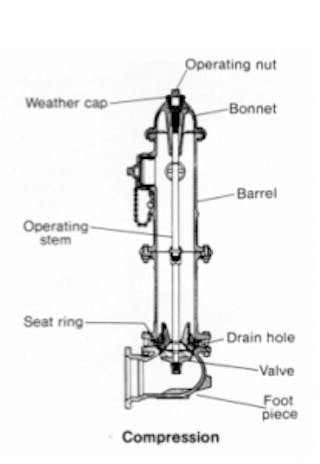

Breaking Down Components Of A Fire Hydrant

The Case For Inspecting Fire Hydrants Waterworld

Series 27 Dry Barrel Fire Hydrants American Avk

How Fire Hydrant Is Made Material Making Used Components Dimensions Machine

Can Fire Hydrants Be Used In Freezing Cold Weather Quora

Why Are There Different Fire Hydrant Designs Is It Important Quora

0 comments

Post a Comment